木工机械解决方案

木工轴承工作现状分析

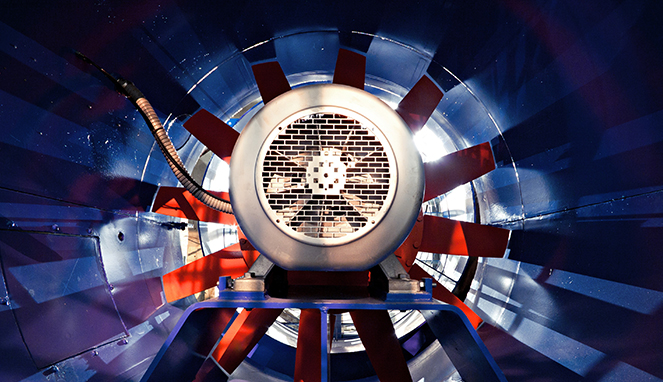

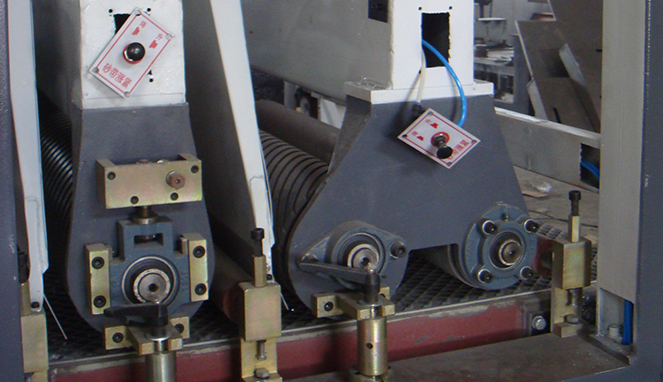

高转速

砂光机涨紧辊轴承在抛光时,转速可达 2800r/min;

要求长寿命

要求轴承长期无故障运行;

间歇式交变负荷

在抛光木料时,由于木料的不平整性,轴承需承受间歇式的交变负荷。

环境高污染

在木料加工过程中,会产生大量的粉尘和木屑,轴承工作环境非常恶劣

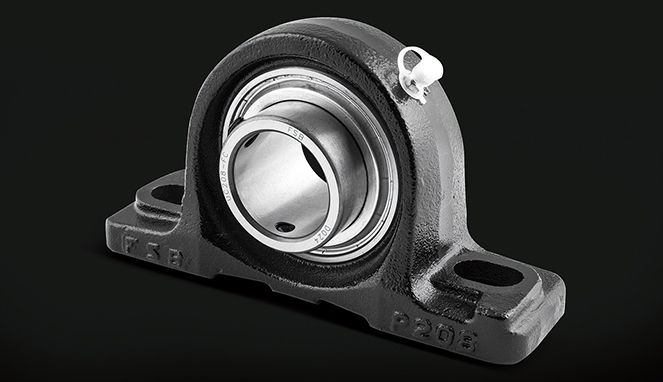

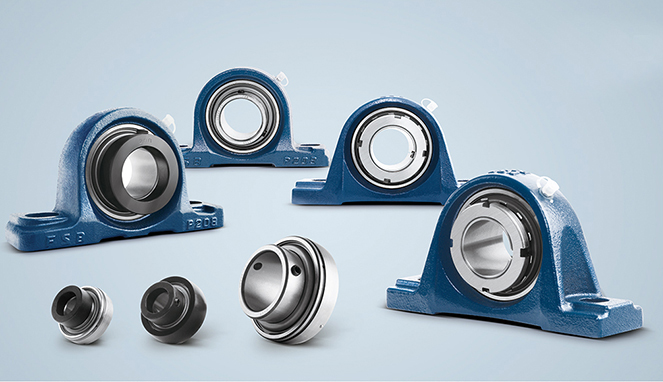

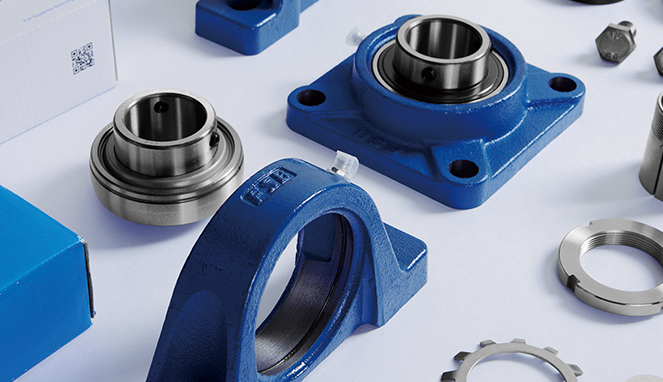

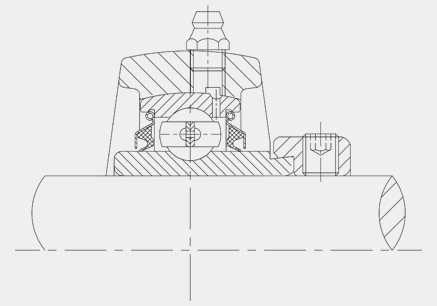

福山轴承对木工机械的解决方案

基于木工机械现场经验和调查反馈,福山公司有一系列针对性的解决方案。并研发出木 工机械专用轴承。

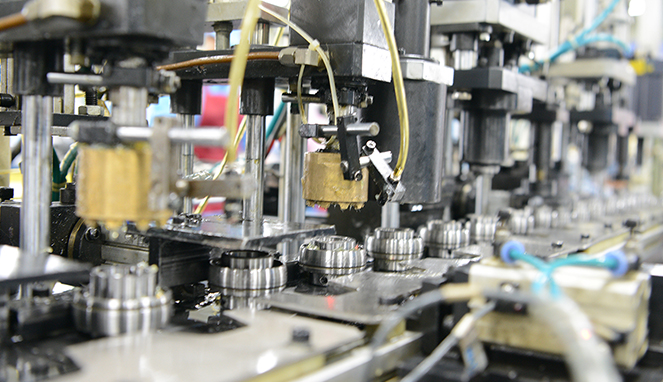

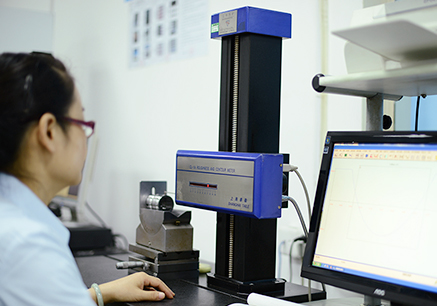

轴承材料

采用国内高纯度轴承钢,提高轴承的稳定性,使轴承寿命可延长 30%以上;

适配的润滑脂

采用高品质的电机油脂及润滑技术,使轴承寿命和可靠性得到有效的提高;

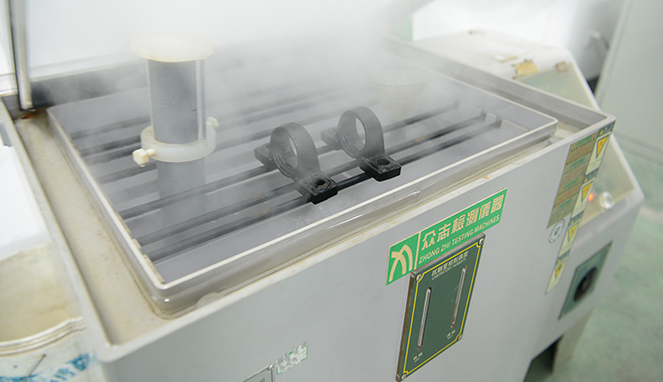

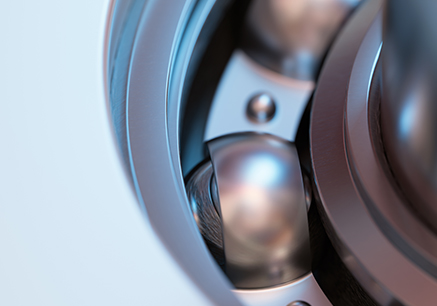

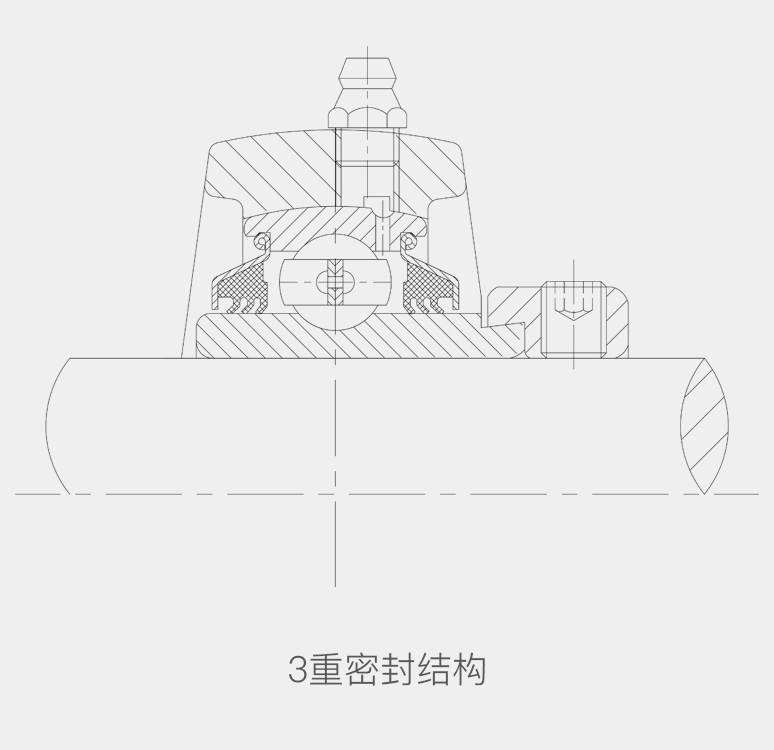

改善的密封结构

针对木工机械使用工况,研发出木工轴承专用密封圈,具有轻扭矩,高防尘,不松动的 特性,并获得专利版权;和同规格的轴承在相同的条件下做防尘试验,其防尘性能提高了 45%。

轴承沟道的优化设计

轴承沟道参数的优化调整及特殊的加工工艺,减少沟道的摩擦系数,改善了润滑油在工 作过程中的合理分布,使其在高转速下仍然可以保持有效的润滑和较低的噪音水平