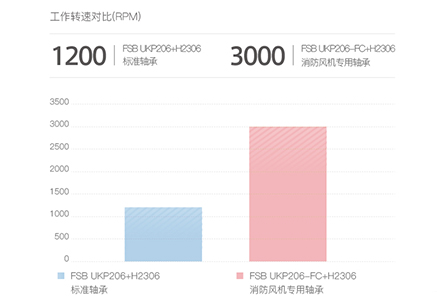

高转速低噪音

全新的密封理念、P6精度控制、可达3600r/min、满足您低噪音、长寿命的使用需求

F1普通风机轴承

FC消防风机轴承

FA商用风机轴承

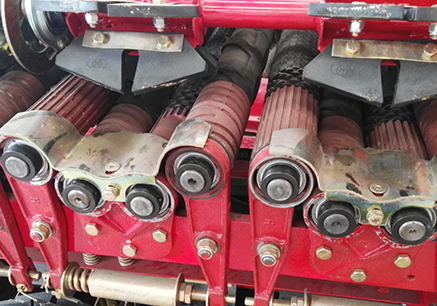

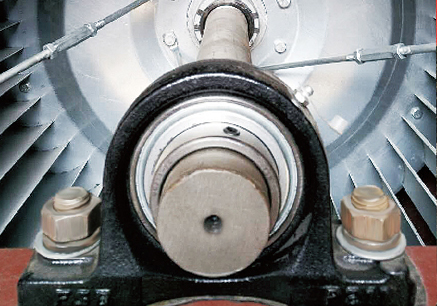

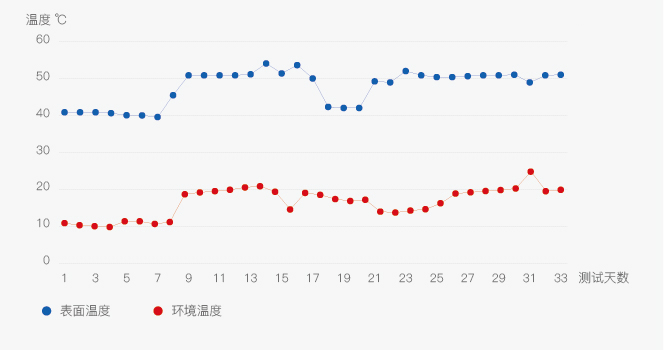

F 系列风机专用轴承疲劳测试

测试产品:HCP208-F1

测试要求:不间断电

测试速度:3300rpm,5XSPB 皮带加大皮带张力

温升:≤20°C

测试时间:2015年2月10日至2015年3月24日

噪音表现:未出现明显的噪音变大或异响

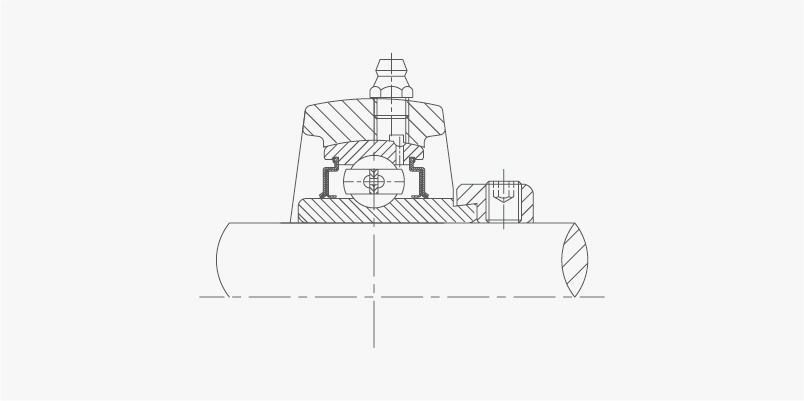

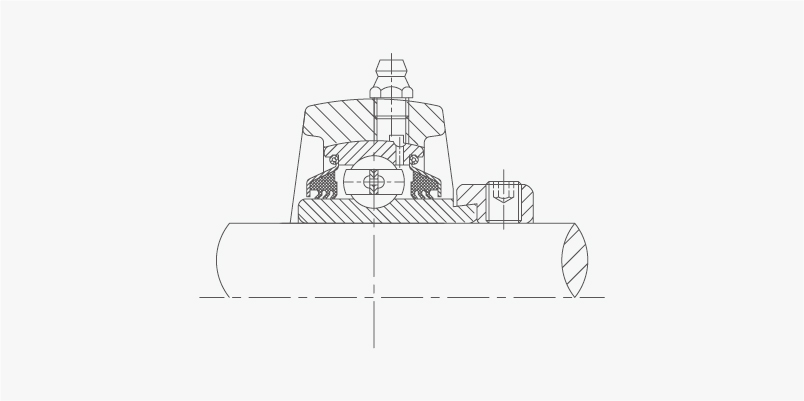

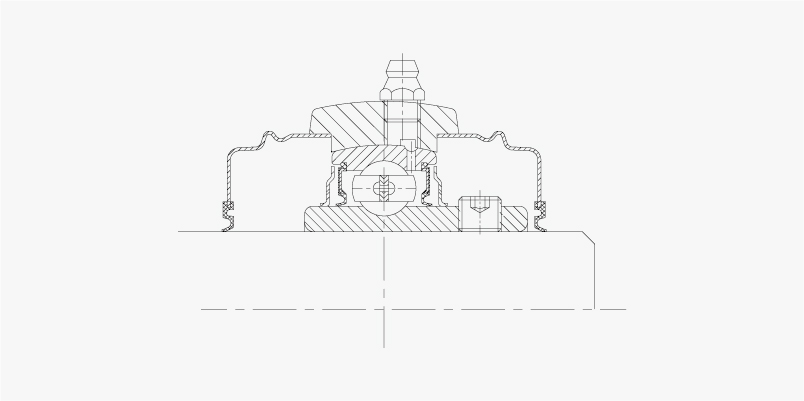

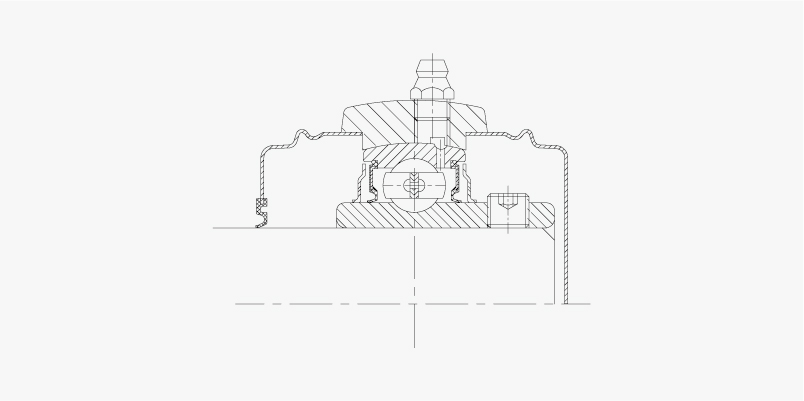

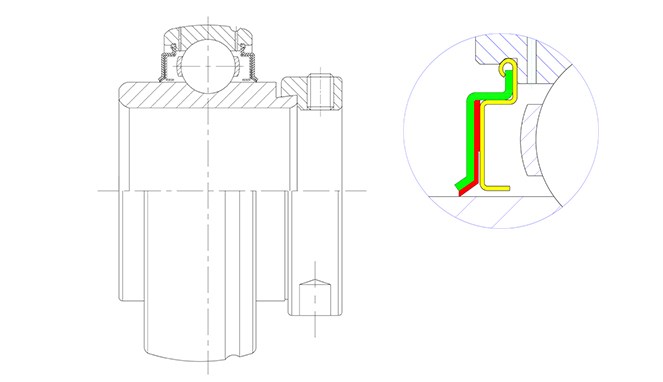

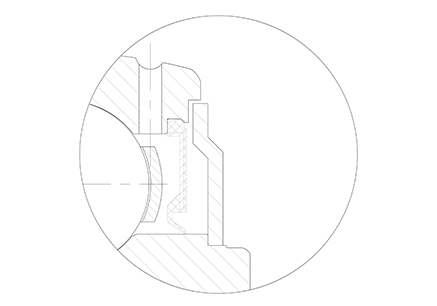

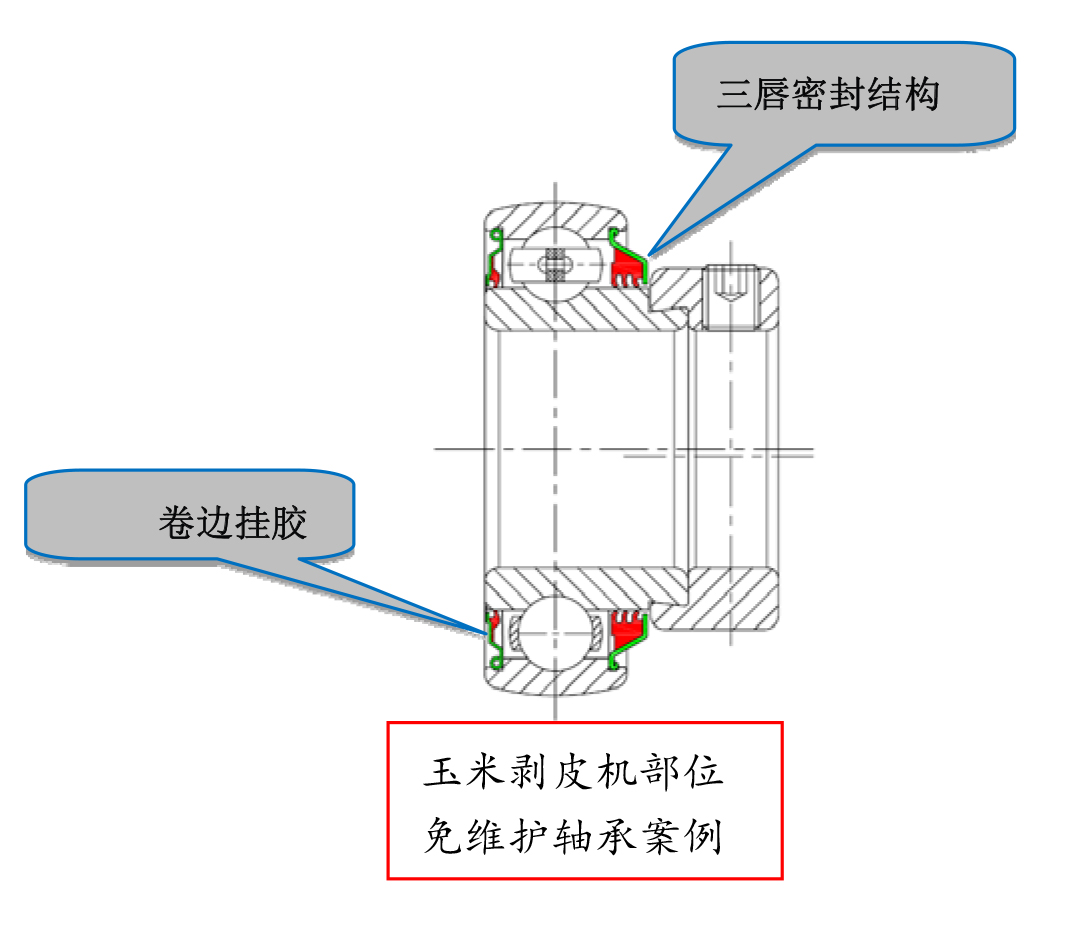

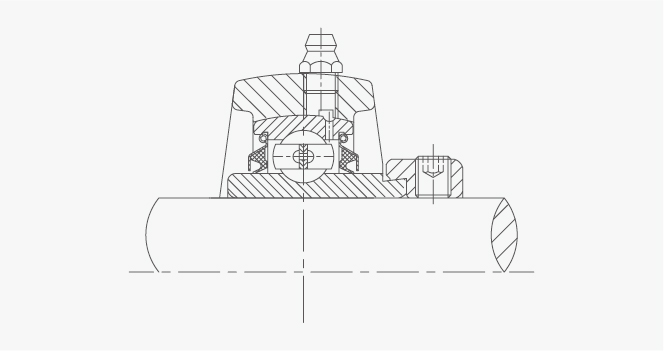

R8 密封结构

具有划时代的风机专用密封圈横空出世,

并已获得专利版权,

一改先前密封圈的风格,

同时具有轻扭矩、高防尘、

不易松动的特性,

满足您安全可靠的使用性能。

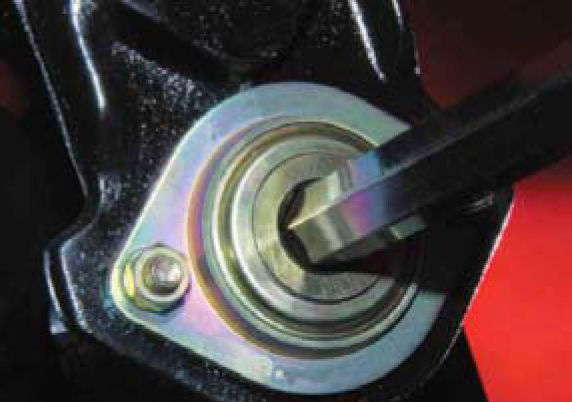

防松尼龙顶丝

在振动、高速运转等使用条件下具有极强的紧定效果。

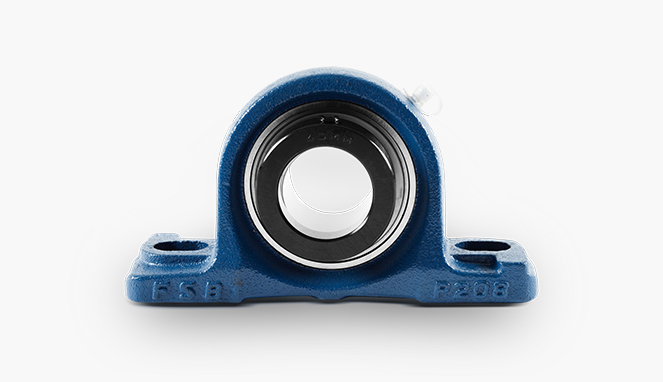

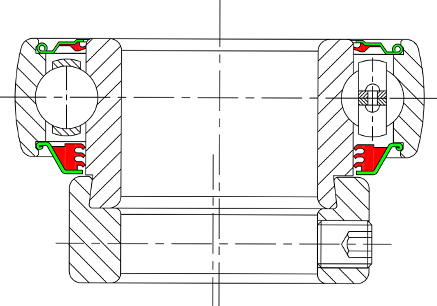

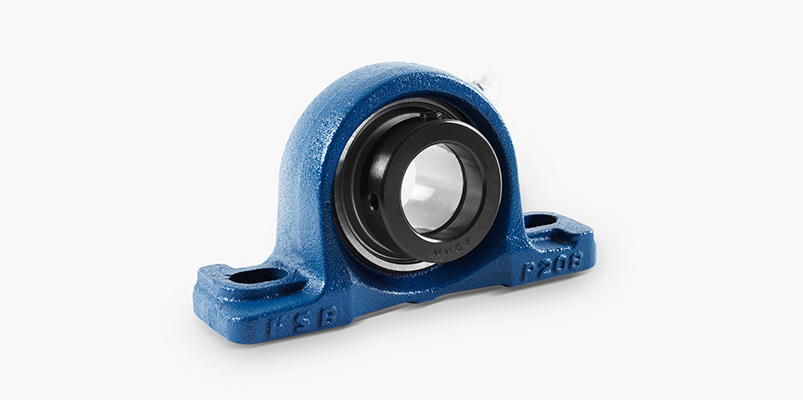

F1普通风机轴承

100%音频振动检测

特定风机游隙标准

可有效降低高速运转时的振动和噪音

防松尼龙顶丝

适配的电机脂 L02

保证轴承长期低噪音平稳运转

风机专用密封圈 R8

轴承芯与轴承座的特定配合 JH7

更适宜风机的运行工况,使轴承不承受异常载荷,保持优异的运转性能

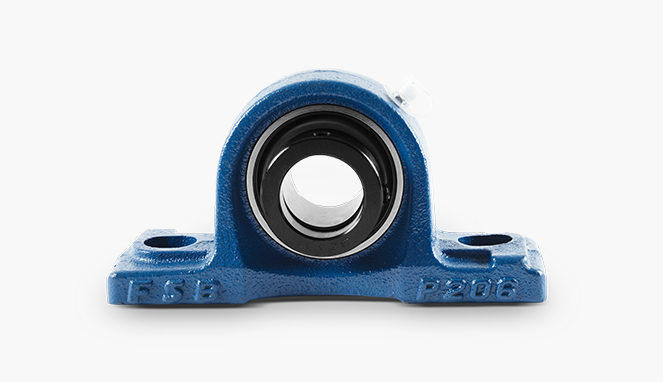

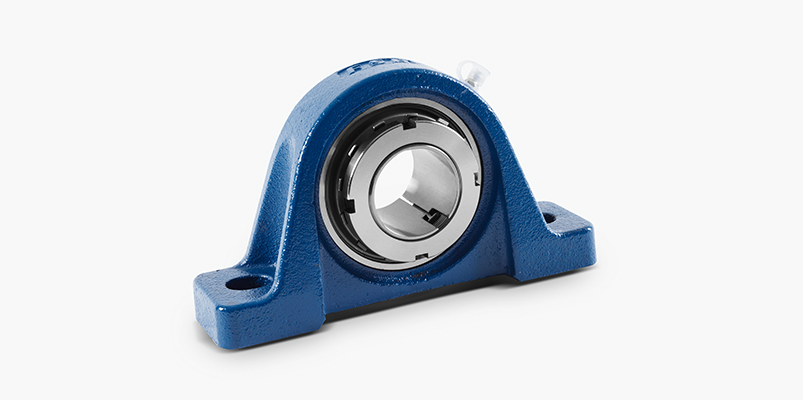

FA 商用风机轴承

100%音频振动检测

特定风机游隙标准

可有效降低高速运转时的振动和噪音

防松尼龙顶丝

适配的电机脂 L02

保证轴承长期低噪音平稳运转

风机专用密封圈R8

轴承芯与轴承座的特定配合 JH7

更适宜风机的运行工况,使轴承不承受异常载荷,保持优异的运转性能

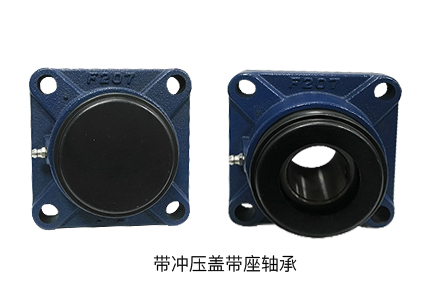

坚固可靠的加强筋轴承座

轴承芯材料采用精炼钢

FC 消防风机轴承

符合公安部消防局GA211-2009实验要求

工作温度可达300℃

洛阳轴承研究所检测验证轴承寿命:

每天8小时或长时间连续运转可达400-8701021h 以上

100%音频振动检测

特定消防风机游隙

防松尼龙顶丝

进口高温油脂 L15

风机专用耐高温密封圈 R8

轴承芯与轴承座的特定配合 JH7